Bambanci tsakanin walda Laser na mutum-mutumi da waldi mai karewa

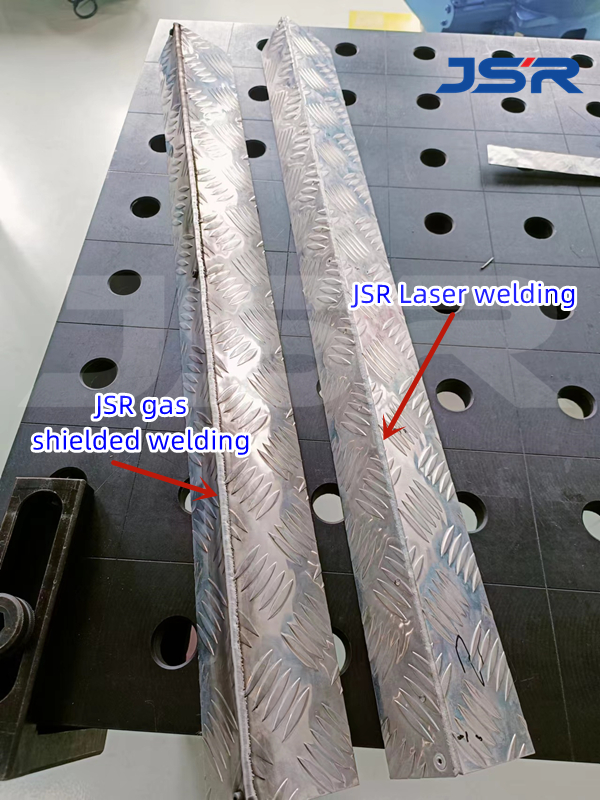

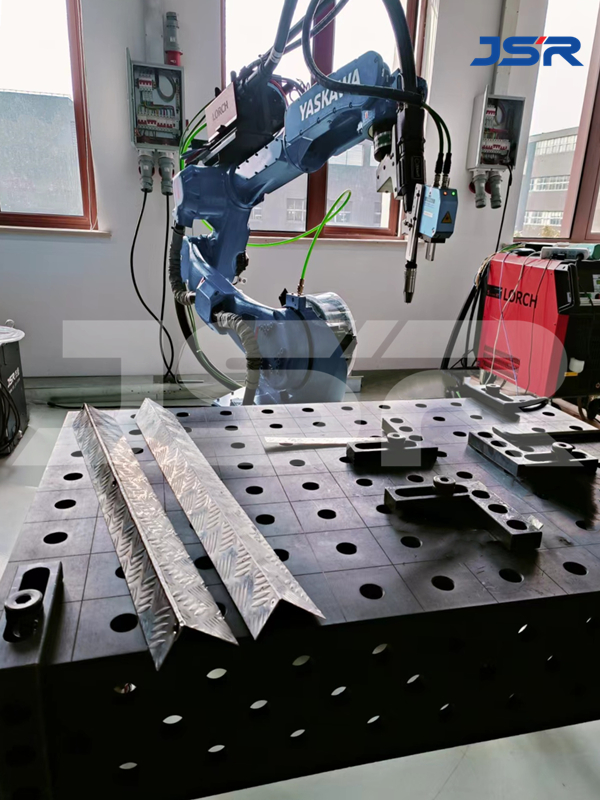

Weld ɗin Laser na Robotic da walda mai kariya na gas sune fasahohin walda na yau da kullun. Dukansu suna da nasu fa'idodin da yanayin da ake amfani da su a cikin samar da masana'antu. Lokacin da JSR ke sarrafa sandunan aluminum da abokan cinikin Ostiraliya suka aiko, yana amfani da waɗannan hanyoyin biyu don gwajin walda. Mai zuwa shine kwatancen tasirin walda na sandunan aluminum, kamar yadda aka nuna a cikin adadi:

Mene ne Laser waldi?

Robotic Laser walda: Ana amfani da katako na Laser don dumama kabu ɗin walda zuwa yanayin narkewa, kuma ana samun ingantaccen walda ta hanyar daidaitawa na kan waldawar Laser.

Menene Welding garkuwar Gas?

Walda mai garkuwar iskar gas: Ana amfani da bindigar walda don samar da zafi mai zafi ta hanyar baka na wutan lantarki, wanda hakan ke sa kayan walda ya narke yayin da wurin walda ke kare shi daga iskar oxygen da sauran gurɓatawar waje ta iskar kariya (yawanci iskar gas mara ƙarfi).

https://youtube.com/shorts/Hfyqm0_tJ6c

Robot Laser waldi VS Gas kariya waldi

1. Abubuwan da ake buƙata:

• Robot Laser waldi: More dace da bakin ciki kayan, kamar bakin karfe, aluminum gami, da dai sauransu.

• walda mai garkuwar robot: Yana da aikace-aikace masu faɗi akan zanen ƙarfe masu kauri, gami da ƙarfe.

2. Gudun walda:

• Robotic Laser waldi: Yawanci saurin waldawa yana da sauri kuma ya dace da yanayin samarwa mai girma. A workpiece waldi gudun na JSR abokan ciniki ne 20mm / s.

• Gas-garre waldi: The waldi gudun ne kullum hankali fiye da Laser waldi, amma shi ne har yanzu wani muhimmin zabi ga wasu musamman workpieces da kuma al'amuran da mafi girma bukatun. Gudun waldi na workpiece a cikin hoton shine 8.33mm/s.

3. Daidaitawa da Sarrafa:

• Robot Laser waldi: Laser waldi yana da high bukatun a kan kayayyakin. Idan akwai gibi a cikin gidajen abinci, zai shafi waldawar laser. Yana da babban mataki na daidaito da kuma sarrafawa, kuma ya dace da lokatai waɗanda ke buƙatar ingancin walda mai mahimmanci.

• walda mai garkuwar iskar gas: Yana da yawan jure rashin kuskure don samfur kuma ana iya walda shi koda kuwa akwai gibi a cikin tsagawar samfur. Daidaiton ya ɗan yi ƙasa da na walƙiya na Laser, amma har yanzu ana iya amfani da shi a wasu aikace-aikacen tare da buƙatun sako-sako.

4. Tasirin walda:

• Robotic Laser waldi: Saboda ƙananan zafi shigar, Laser waldi yana da ƙasa da thermal tasiri a kan workpiece, da weld kabu yana da lebur da santsi bayyanar.

• Gas garkuwa waldi: Saboda da high waldi zafin jiki, da waldi surface ne sauki kumbura, don haka ya dace da workpieces cewa bukatar polishing.

Zaɓin waldi na Laser na robotic ko waldi na garkuwar gas ya dogara da takamaiman bukatun samarwa, gami da la'akari da kayan aiki, buƙatun ingancin walda, ingantaccen samarwa, sarrafa kayan aiki, da sauransu.

Lokacin aikawa: Janairu-23-2024