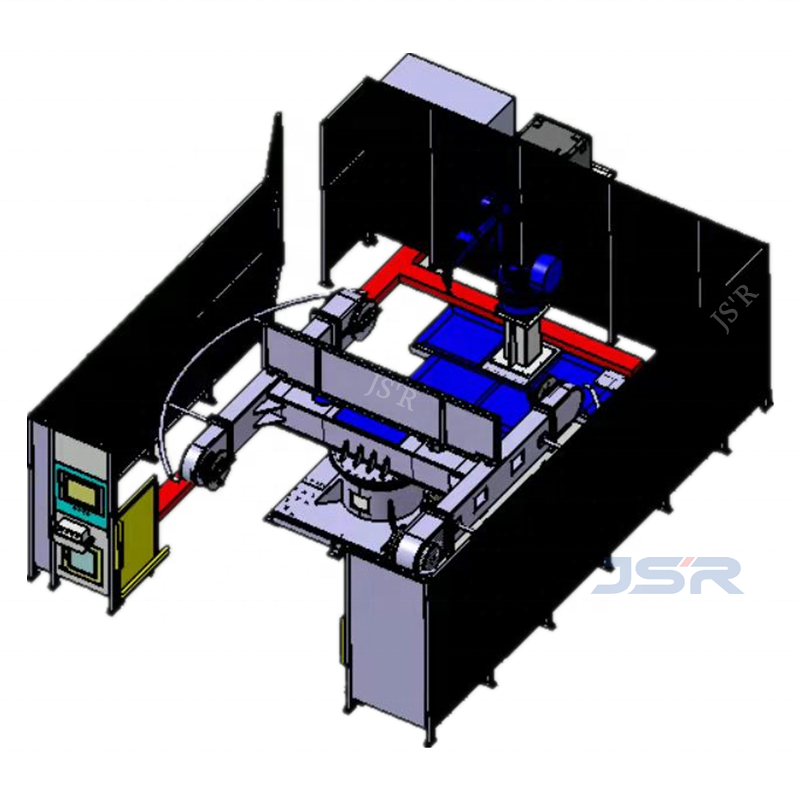

Wuraren aiki na Robotic bayani ne na sarrafa kansa wanda ke da ikon yin ƙarin hadaddun ayyuka kamar walda, sarrafawa, kulawa, fenti da taro. A JSR, mun ƙware wajen ƙira da ƙirƙirar keɓaɓɓen wuraren aiki na mutum-mutumi don aikace-aikace iri-iri dangane da buƙatun abokan cinikinmu da buƙatunmu yayin haɓaka farashi da haɓaka aiki.

Wuraren aiki na Robotic sun ƙunshi abubuwan da ake buƙata don mutum-mutumi, ko robobi da yawa, don yin ayyuka akan layin wargajewa da palletizing. Waɗannan kayan aikin na iya haɗawa da kyamarar hangen nesa ta 3D, gripper, , allon sa ido na aiki tare, waƙa/ dogo, matsayi, da ƙari. Maimakon yada kowane mataki a tashoshi daban-daban, saitin aikin mutum-mutumi yana aiwatar da gabaɗayan tsari a tashar.

A ainihin su, wuraren aikin mutum-mutumi suna sarrafa abubuwan da aka gyara zuwa wani takamaiman matsayi ko cikin taron don marufi, jigilar kaya, ko amfani na gaba. Tare da wannan aikin, JSR na iya ƙirƙira wuraren aikin mutum-mutumi waɗanda ke ɗaukar matakan gamawa kamar:

Abubuwan jigilar kayayyaki: Za a iya shigar da wuraren aiki na robotic tare da kayan aiki mai sarrafa kansa don lura lokacin da aka kammala aikin taro kuma a matsar da taron zuwa tashar ta gaba a cikin tsarin masana'antu.

Me yasa Ake Amfani da Tashoshin Aiki na Robotic?

Automation ƙari ne mai fa'ida ga kusan kowane tsarin masana'antu saboda yana ƙara sauri, yana ƙara amincin ma'aikaci, kuma yana rage haɗarin kuskuren ɗan adam ko rashin daidaituwa. Wuraren aiki na robotic sun ma fi fa'ida saboda suna iya ɗaukar ayyuka masu sarƙaƙƙiya da sarrafa duka matakin haɗuwa gabaɗaya da kuma sauyawa zuwa mataki na gaba. Wasu takamaiman fa'idodin wuraren aikin mutum-mutumi sun haɗa da:

inganci

Hanyoyin sarrafawa ta atomatik na iya yin tsayin daka ba tare da ƙara yuwuwar kurakurai ko ingancin aikin da bai dace ba. Ko da a lokacin da ayyuka masu sarrafa kansa suka ɗauki tsawon lokaci fiye da aiwatar da aikin hannu, wanda ba kasafai ba ne, ƙarar tsawon lokaci yana haifar da ƙarin haɗe-haɗe.

Daidaitawa

Wuraren aiki na Robotic suna bin umarnin da aka saita da ƙayyadaddun bayanai don yin ayyuka da tabbatar da aikin ya cika ka'idojin da aka saita. Wannan yana haifar da ƙarin daidaiton fitarwa daga farkon zuwa ƙarshe, ko da yayin da ayyukan haɗaɗɗiyar ke zama mafi rikitarwa. Yin amfani da wuraren aikin mutum-mutumi don kammala ayyuka, kamar walda, yana haifar da ingantaccen samfur.

Adana

Wuraren aiki na Robotic suna haɓaka ƙimar-daidaituwar ayyukan taro. Kayan aikin sarrafa kansa suna aiki da tsayi da sauri fiye da tsarin aikin hannu kuma baya buƙatar albashi, fa'idodi, ko wasu kuɗaɗen taimako. Yayin da fasaha ke ci gaba da karuwa, ƙirƙira, kiyayewa, da kuma gyara tsarin na'ura na mutum-mutumi ya zama mafi araha.

Tsaro

Wuraren aiki na Robotic suna ɗaukar ayyuka waɗanda in ba haka ba za su iya haifar da haɗari ga ma'aikatan ɗan adam, gami da ayyuka masu amfani da kayan aiki masu kaifi, hanyoyin da ke amfani da sinadarai masu guba ko masu guba, da matakai tare da injuna masu nauyi ko sassa. Saboda wuraren aiki na mutum-mutumi suna sarrafa samfuran kai tsaye, ma'aikacin ya shiga hulɗa da ƙananan haɗari masu yuwuwa. A JSR, muna gina wuraren aikinmu na mutum-mutumi don haka sassan mutum-mutumi da kansu suma suna haifar da haɗari kaɗan ga ma'aikacin. Kowane tantanin halitta na iya haɗawa da fasalulluka na aminci kamar shinge, garkuwa don toshe hasken baka, tsayawar gaggawa, da na'urorin daukar hoto.

Tuntuɓi JSR don ayyukan Robotic A yau

Wuraren aiki na robotic suna haɓaka aiki da amincin wuraren da ke gudanar da ayyukan taro. A JSR, ƙwararrun ƙwararrun ƙwararrun mutum-mutumi za su iya ƙirƙira wuraren aikin mutum-mutumi na al'ada waɗanda ke aiwatar da daidaitattun hanyoyin haɗuwa da na musamman don kasuwancin ku. Tuntube mu yau don farawa.

Duba Binciken Harkarmu A Kasa

menene matsalar abokin cinikinmu?

Abokin cinikinmu yana buƙatar cire barbashin filastik daga jaka (kg 50 kowannensu)

Maganin mu:2

Mun yi amfani da mutum-mutumi mai nauyin kilogiram 180. 3D hangen nesa kamara da al'ada robot gripper,Yana goyan bayan karya jaka na girma dabam dabam. Kyamarar hangen nesa ta 3D tana ɗaukar hoto guda ɗaya don samun bayanan 3D na duka buhunan buhu. Yana da sauri da inganci. Robot ɗin ya kama ya karya kayan injin jakar, da girgiza, don tsaftace sauran kayan yadda ya kamata.

Lokacin aikawa: Dec-07-2023